06 March 2020

LACROIX Electronics

Smart Industry is highly prized by the Electronics activity of LACROIX, and this is reflected on an everyday basis across all its production sites, not just in France, but in Germany, Tunisia and Poland. The new uses of virtual reality in training, and augmented reality at the heart of the production tool all point in the same direction: harnessing new technologies to meet human needs.

In Poland, virtual reality offers a real training solution

Training new recruits is a major challenge for the Electronics activity of LACROIX. Before starting work on a production chain, freshly recruited operators must successfully master a set of specific skills safely and at an appropriate speed.

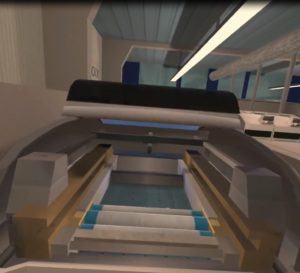

To familiarise themselves with their new environment without disrupting production flow, what could be better than a virtual immersion in their future work station? Simply by donning a virtual reality headset, the employee can be transported into their future working environment alongside an automated SMD (surface-mounted device) line, and can therefore get to grips with their work station by learning how it operates in a virtual environment.

This project, known as Digital training for production was developed internally at the initiative of one of the team members, assisted by a team of IT students from a local college.

The training provided with this new tool, which is both precisely targeted and enjoyable, has generated good feedback and produced better results than conventional learning methods. By encountering different situations virtually, new operators can learn how best to react. Plus, seeing the work station in advance reduces their stress when they join the production line.”

A la carte augmented reality in France

Innovation plays a key role within the other LACROIX sites in Tunisia and Germany, and is of course at the heart of the French factory in Saint-Pierre-Montlimart, where augmented reality technology has been developed to assist operators during the cross-cutting component assembly stages.

For this project, the electronics sub-contractor has formed a partnership with a start-up based in the south of France, Robocortex. No need for a virtual reality headset: a simple projector displays certain items of information directly on the work station, such as instructions for the current stage of production or precise areas on the printed circuit board.

For this project, the electronics sub-contractor has formed a partnership with a start-up based in the south of France, Robocortex. No need for a virtual reality headset: a simple projector displays certain items of information directly on the work station, such as instructions for the current stage of production or precise areas on the printed circuit board.

This assistance provides a real gain in quality and performance, particularly for the complex cards we produce in small batches. Technicians assisted by light beams, for example, no longer need to constantly raise and lower their head to look at a plan.

This kind of help is invaluable, since this technology reduces arduous tasks in the workplace and gives the operator peace of mind by reducing their risk of error. We are continuing the exploration of Augmented Reality, as for example the soon test of a holographic guidance system.

Augmented and virtual reality is gradually becoming part of the industrial landscape of the Electronics activity of LACROIX. And this is only the first stage before a more widespread deployment across all sites.

For more info, please contact Dominique Maisonneuve, Smart Industry Manager.

DISCOVER THE PRODUCTION SITE IN FRANCEDiscover the production site in Poland

Plus d'articles

Explained

3 good reasons to relocate your electronic production close to your customers

Cobots: Man’s new ally ?

3 tips for reshoring through automation

Explained

Scalable Industrial Automation: Flexibility and Efficiency for the Factory of the Future

Explained